A glimpse into our work

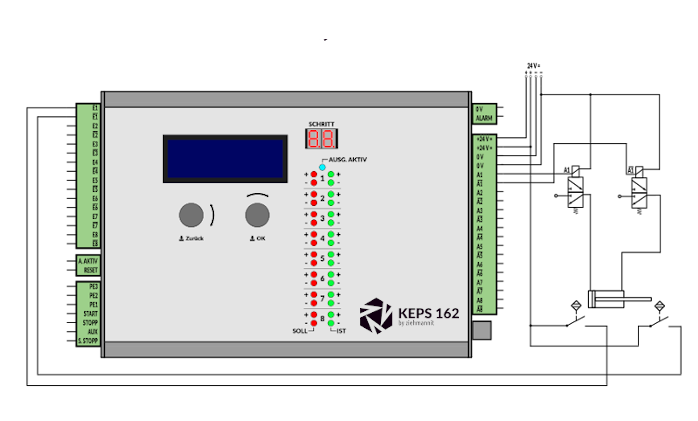

KEPS 162

A custom solution for the automation of pneumatic controls

The KEPS 162 is a programmable logic controller (PLC) designed for the electrical control of pneumatic valves. It serves as a direct replacement for the Kuhnke KUAX Control 62.000 and is compatible both mechanically and electrically.

With 16 inputs and 16 outputs, divided into 8 independent channels, the KEPS 162 enables precise control of up to 8 cylinders, each with two limit switches.

The controller stores programs in non-volatile memory – eliminating the need for a battery. Programming can be done directly while installed, without requiring additional accessories or a PC.

The KEPS 162 features an intuitive learning function: program steps can be recorded directly by activating the limit switches. This allows for quick and straightforward process adjustments.

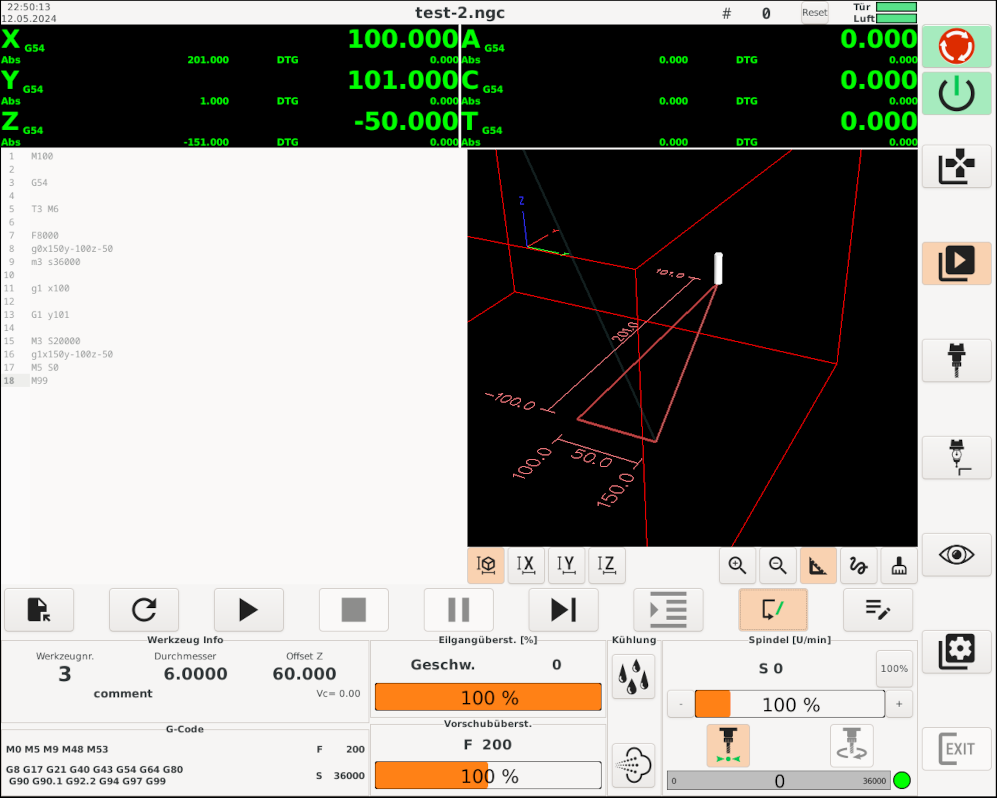

Partus CNC

Retrofit of CNC Machines

As part of a comprehensive retrofit, the control electronics of an existing Partus Sinus Automation CNC machine were completely replaced, while the motors and mechanical structure were retained. The outdated control system was replaced with modern components, resulting in a significant reduction in downtime and an optimization of manufacturing processes.

The new control software is based on LinuxCNC, which controls the Kollmorgen AKD servodrives and Beckhoff IO components via EtherCAT. To continue using the existing Sanyo motors, a translator hardware was developed. The custom-built EncConv device translates the Sanyo motor encoding in realtime into the Tamagawa protocol, which is supported by the Kollmorgen AKD servodrives.

Thanks to these adjustments, the CNC control was converted from a specialized solution to LinuxCNC. Existing machining programs can still be used, while additional features can be added as needed.

Additionally, the user interface was customized according to the customer's requirements, maintaining existing workflows as much as possible and reducing the training effort.

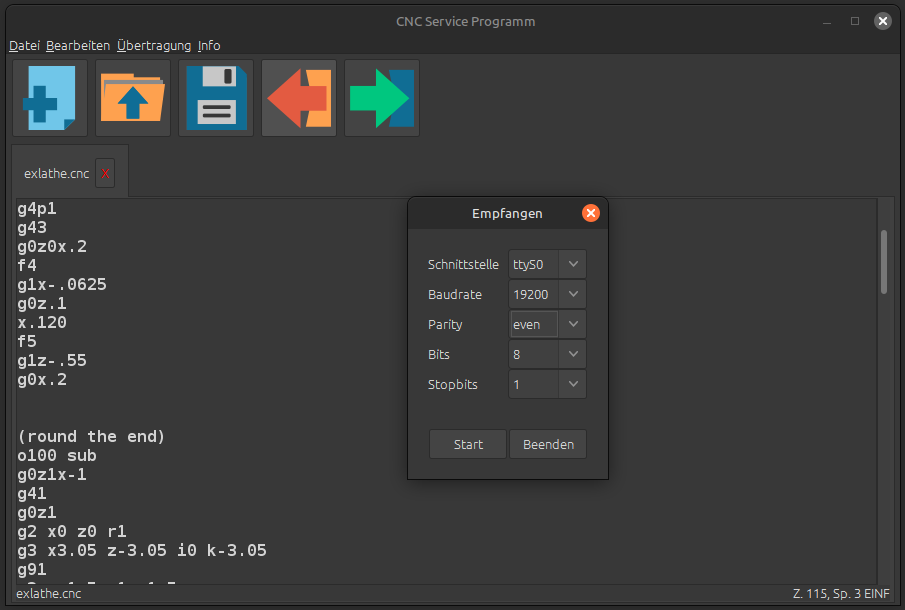

CNC Service Program

Manage and process scan jobs efficiently

Our CNC Service Program enables reliable, bidirectional communication between old CNC controllers and modern systems via a USB-to-serial interface.

It supports both sending and receiving data, ensuring seamless integration of older machines into modern production environments.

With flexible parameters such as baud rate, parity, data bits, and stop bits, we tailor the communication to meet the specific requirements of your CNC controller.

This ensures a data transfer that integrates your machines into the current production process.

Scan22

Manage and process scan jobs efficiently

Scan22 enables the central creation and management of scan tasks in the TWO system before they are processed directly at the selected scanners using the practical and user-friendly Scan22 hardware. The preparatory bundling of documents and the shared use of resources make the entire scanning process significantly more structured and efficient.

Especially in administrative environments and areas with high document volumes, Scan22 brings a significant improvement in the organization and processing of scan tasks.

Scan tasks can be created remotely, significantly increasing flexibility and speed when assigning tasks. Additionally, the task division between multiple users allows several people to create and process tasks in parallel.

Furthermore, Scan22 ensures that the confidentiality of scanned documents is maintained and prevents sending scans over insecure channels.

By optimizing the workflow, unnecessary walking distances are eliminated, making the processing of large document volumes much easier. Scan22 is especially suitable for environments with high scan volumes and multiple users accessing a single device.

TWO Transformative Web Offering

The heart of our software

TWO is the central foundation of our software ecosystem, serving as the backbone for a wide range of applications (e.g. this website). The platform seamlessly integrates data processing, hardware and software connectivity, and customizable plugins within a powerful and flexible environment.

Originally designed as a secure cloud storage solution, TWO has evolved into a scalable and modular infrastructure that adapts effortlessly to diverse business requirements. Thanks to its dynamic plugin system, new features can be added at any time, significantly accelerating development cycles—what once took months can now be achieved in weeks or even days.

TWO’s capabilities are further enhanced by AI-powered speech recognition, utilizing local Large Language Models (LLMs) to enable secure and efficient voice input.

With its open architecture, TWO integrates seamlessly into existing systems and hardware, allowing businesses to leverage their current infrastructure without disruption. Security remains a top priority: most customers opt for on-premises hosting,but we also provide expert guidance on external hosting and backup strategies to ensure maximum data protection.

With TWO, businesses gain a flexible, secure, and high-performance platform that evolves with their needs and can be customized to meet specific requirements.